Habka calending sagxada PVC waa hab wax soo saar hufan oo joogto ah, kaas oo si gaar ah ugu habboon soo saarista go'yaal qaab-dhismeed isku mid ah iyo kuwo la daadin karo (sida sagxadaha dabaqa ah ee isku midka ah ee ganacsiga). Udub dhexaadkeedu waa in PVC-ga dhalaalaysa laga dhigo lakab dhuuban oo isku mid ah iyada oo loo marayo calendarka duubka badan, ka dibna la qaboojiyo si uu u qaabeeyo. Kuwa soo socda waa tillaabooyinka gaarka ah iyo qodobbada xakamaynta farsamada ee muhiimka ah:

I. Geedi socodka kalandarka

Daaweyn Walxaha Ceyriinka ah> Isku darka kulul ee xawaaraha sare leh, qaboojinta iyo qaboojinta isku darka, isku darka gudaha iyo balaastiga, isku darka furan iyo quudinta

Afar duub oo duuban, dhejinta/laminating, qaboojinta iyo qaabaynta, gooynta iyo dabaylaha

II. Qodobbada Muhiimka ah ee Hawl-galka Tallaabo-tallaabo ah iyo cabbirrada Farsamada

1. Dawaynta Walaxda Ceyriinka ah iyo isku darka

Qalabaynta Formula (Tusaale): - Resin PVC (nooca S-70) 100 qaybood, - Plasticizer (DINP / deegaanka saaxiibtinimo ester) 40-60 qaybood, - Calcium carbonate filler (1250 mesh) 50-80 qaybood, - Heat stabilizer (kalsiyum zinc composite) - 3-5 qayb acid - Pigment (titanium dioxide / budada midabka aan organic) 2-10 qaybood

Habka isku dhafka*:

Isku darka kulul: Isku-darka xawaaraha sare leh (≥1000 rpm), kuleyl ilaa 120 ° C (10-15 daqiiqo) si loogu oggolaado PVC-ga inuu nuugo caagagga; Isku darka Qabow: Si degdeg ah u qabooji ilaa 40°C (si looga hortago burooyinka), wakhtiga qaboojinta ≤ 8 daqiiqo.

2. Balaastigga iyo Quudinta

- Isku darka Gudaha: Heerkulka 160-170°C, Cadaadiska 12-15 MPa, Wakhtiga 4-6 daqiiqo → Samaynta cuf caag ah

Fur Mixer: Heerkulka Twin-roll 165±5°C, Gap Roller 3-5 mm

3. Jadwalka afar-roolaha ah (Nidaamka ugu muhiimsan)

- Farsamooyinka Muhiimka ah:

- Xawaaraha Roller Ratio: 1 #: 2 #: 3 #: 4 # = 1: 1.1: 1.05: 1.0 (si looga hortago ururinta walxaha);

- Magdhawga Dhererka Dhexe: Roller 2 waxaa loogu talagalay taajaj 0.02-0.05mm si loo damiyo qallooca kulka. 4. Daaweynta Dusha sare iyo Lamination

Isku-dubbarid: Qalabaynta xargaha (silicone/ steel) heerkulka 140-150 ° C, cadaadiska 0.5-1.0 MPa, xawaaruhu wuxuu ku habboon yahay khadka calending;

Substrate Lamination (Ikhtiyaar): Maro fiber galaas ah/maro aan tolnayn, preheated (100°C), waxa lagu dahaadhay dhalaalidda PVC ee rullaluistu #3 si kor loogu qaado xasilloonida cabbirka.

5. Qaboojinta iyo Qaabaynta

Heerkul qaboojin saddex-heer ah:

Xakamaynta xiisadda: kacsanaanta dabaysha 10-15 N/mm² (si looga hortago qabowga yaraanshaha iyo qallooca).

6. Goynta iyo dabaylaha

- Cabbirka Dhumucda Khadka Tooska ah ee Laser: Jawaab celinta-waqtiga-dhabta ah waxay hagaajinaysaa farqiga u dhexeeya rullaluistemadka (sax ± 0.01mm);

- Si toos ah u gooyn: ballac xaaq ≤ 20mm, dib loo warshadeeyay oo pelletized si dib loogu isticmaalo;

- Dabayl: Dabaysha xarunta xiisadda joogtada ah, dhexroor duudduuban Φ800-1200mm. III. Geedi socodka dhibka iyo xalalka

1. Dhumucda aan sinnayn. Sababta: Isbeddelka Heerkulka Wareegga> ± 2°C. Xalka: Xakamaynta Heerkulka Saliidda Kulaylka-Loop- Xidhan

2. Gaaska dushiisa. Sababta: Dheejinta isku darka oo aan ku filnayn. Xalka: Farooji qasiyaha gudaha (-0.08 MPa).

3. Dildilaaca cidhifyada. Sababta: Qaboojin xad dhaaf ah / kacsanaan xad dhaaf ah. Xalka: Iska yaree xoojinta qaboojinta dhamaadka-dhamaadka kuna dar aag qaboojin tartiib ah.

4. Qaab Dhiman. Sababta: Cadaadis aan ku filneyn oo duuban. Xalka: Kordhi cadaadiska Haydarooliga ilaa 1.2 MPa oo nadiifi dusha sare ee Roller-ka.

IV. Hababka la cusboonaysiiyay ee deegaanka u saaxiib ah iyo waxqabadka

1. Beddelka Xasilinta Ka Xorta ah Leedhka:

Calcium-Zinc Composite Stabilizer + β-Diketone Synergist → Gudub EN 14372 Imtixaanka Socdaalka;

2. Balaastiiste ku habboon deegaanka:

- DINP (Diisononyl Phthalate) → Cyclohexane 1,2-Dicarboxylate (Ecoflex®) Waxay yaraynaysaa Ecotoxicity.

3. Dib u warshadaynta qashinka:

- Burburinta qashinka → Isku-dhafka walxaha cusub ee saamiga ≤30% → Loo isticmaalo soosaarka lakabka hoose.

V. Candering vs. Extrusion (Isbarbardhigga Codsiga)

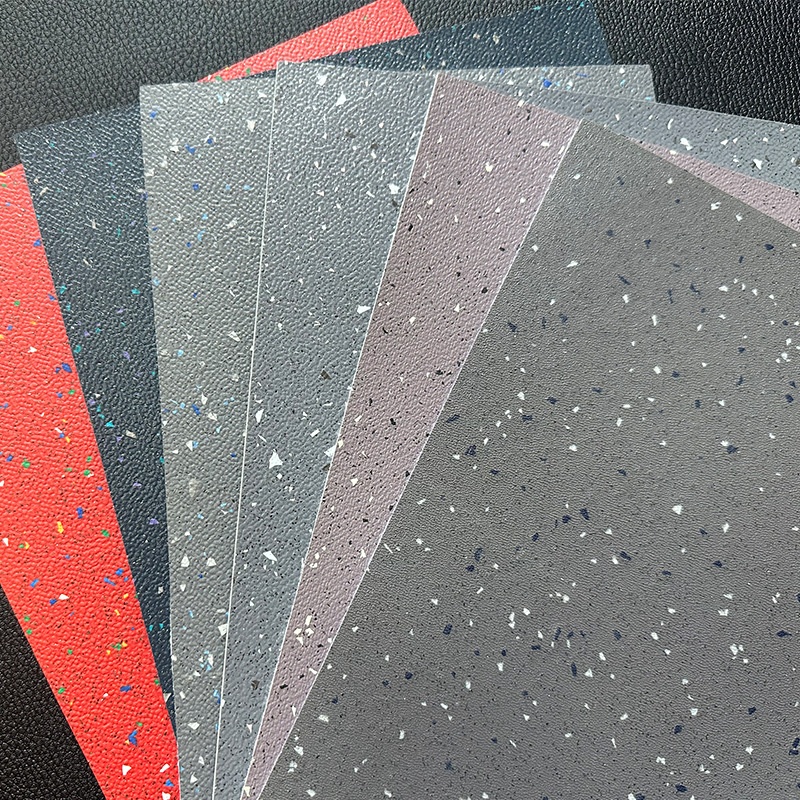

Qaab dhismeedka Alaabta: Dabaqan daloolsan oo isku mid ah/lakab lakabyo badan leh, Lakab lakabyo badan leh oo-baxsan (lakabka u adkaysta xidhashada + lakabka xumbo)

Dhererka Dhumucdiisuna: 1.5-4.0mm (Saaxsanaanta ± 0.1mm), 3.0-8.0mm (Saxe ± 0.3mm)

Dhammaystirka dusha sare: dhaldhalaal sare/qurxin sax ah (ku dayasho hadhuudh alwaax ah), maro/maro qallafsan

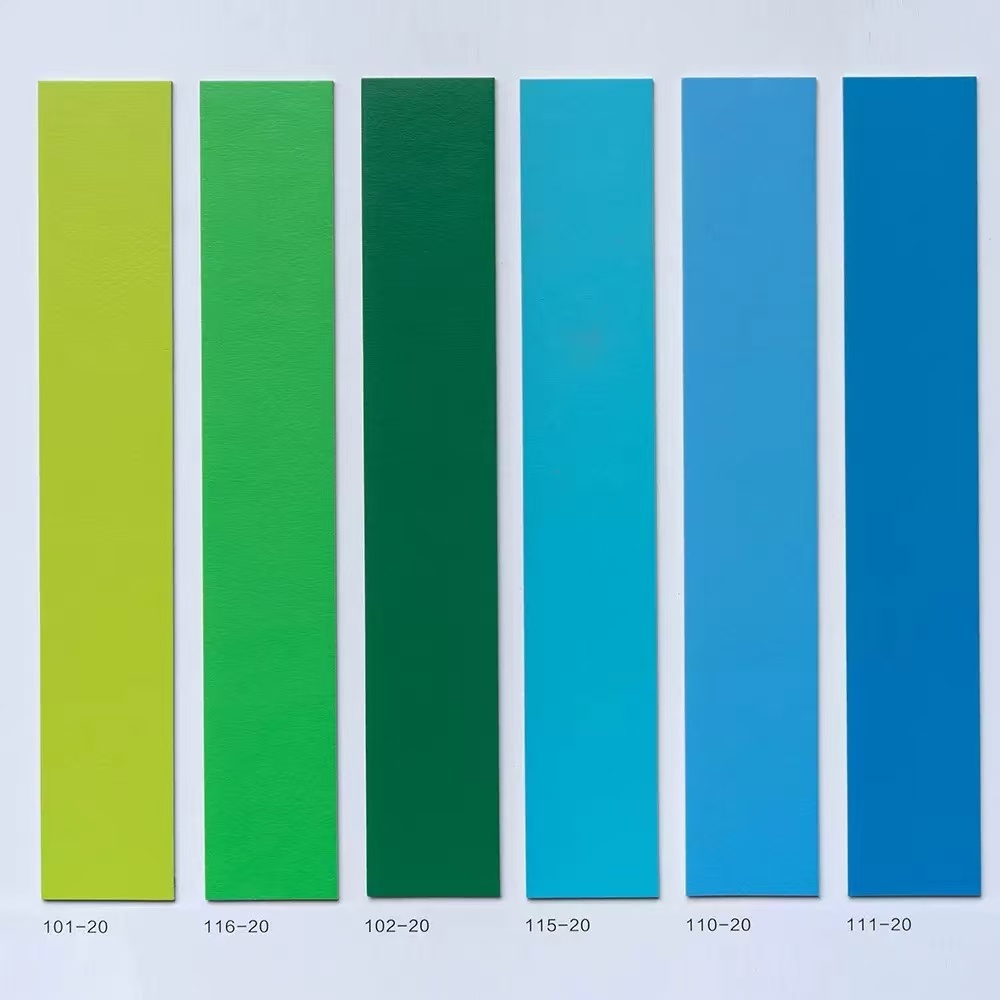

Codsiyada caadiga ah: sagxadaha daloolsan ee isbitaalada iyo shaybaarada, sagxadaha isku xiran ee SPC ee guryaha

Dulucda sheekada

- Faa'iidooyinka Geedi socodka:

- Xakamaynta heerkulka rullaluistemadka saxda ah → isugeynta kala duwanaanta dhumucda <1.5%;

- In-line embossing iyo lamination → Gaadhi saamaynta muuqaalka dhagaxa / birta;

- Alaabta lagu dabaqi karo:

Dabaqa PVC dalool isku mid ah oo leh shuruudaha xasilloonida cabbirka sare (sida taxanaha Tarkett Omnisports);

- Ikhtiyaarada cusboonaysiinta:

- Xakamaynta garaadka: Hagaajinta farqiga roller ee firfircoon ee ku shaqeeya AI (celinta dhumucda-waqtiga-dhabta ah);

- Soo kabashada tamarta: Qaboojinta kulaylka wasakhda biyaha waxaa loo isticmaalaa kulaylka alaabta ceeriin (badbaadinta 30% tamarta).

Fiiro gaar ah: Wax soo saarka dhabta ah, heerkulka calending iyo xawaaraha rullaluistemadka waa in lagu hagaajiyaa iyadoo loo eegayo dheecaanka formula (dhalaalaan index MFI = 3-8g / 10min) si looga fogaado hoos u dhac (tusmada huruud ΔYI <2).

Waqtiga boostada: Jul-30-2025